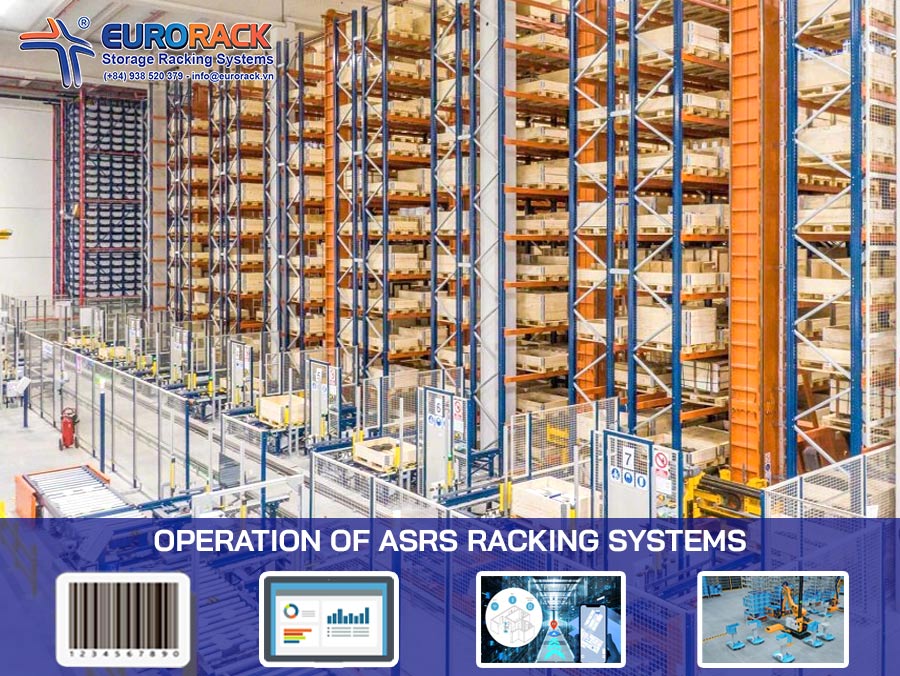

Full Automation with Sensor-Based Retrieval

The Eurorack ASRS Racking System offers a comprehensive solution for businesses seeking speed, precision, and maximum warehouse performance. Built on advanced sensor-based retrieval principles, the system fully automates the entire process of receiving and dispatching goods. This eliminates manual handling, greatly accelerates cycle times, and positions ASRS as a superior alternative to traditional warehousing methods.

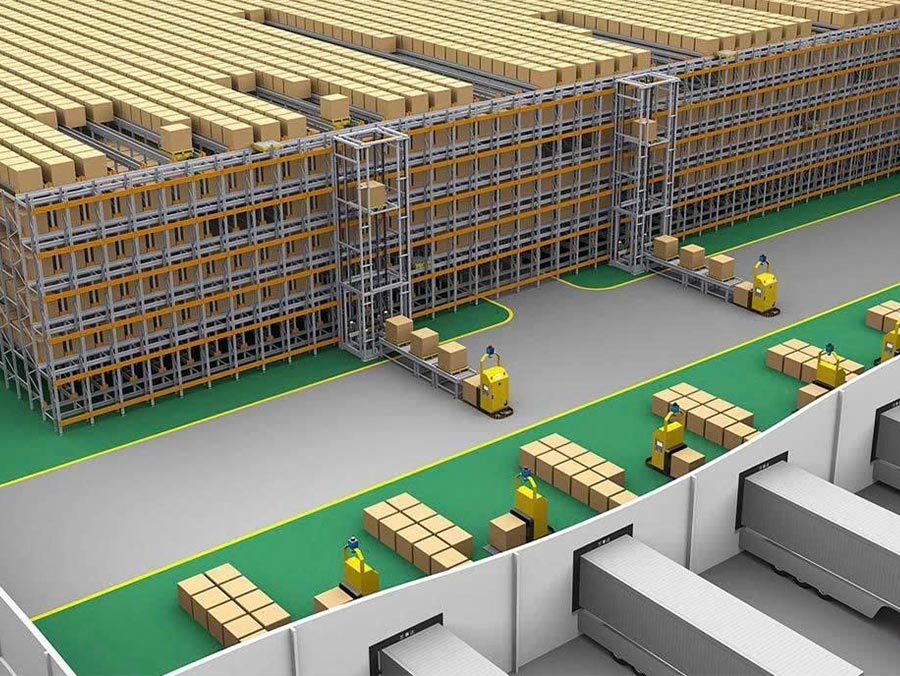

Maximum Space Utilization

One of the most important advantages of the Eurorack ASRS is its ability to maximize available space. Because it operates without the need for multiple aisles, the system achieves an extremely high storage density. The compact, centralized racking design makes it especially valuable for warehouses with space limitations or vertical expansion needs.

High-Capacity Storage for Diverse SKUs

The system is capable of managing and storing a wide variety of SKU codes, even across warehouse footprints exceeding 10,000 square meters. It supports high-bay storage with exceptional efficiency, making it ideal for industries with large and diverse inventories.

Real-Time Inventory Monitoring and Control

Inventory control is another strong point. Eurorack ASRS integrates advanced warehouse management software that enables automated monitoring, area-specific access control, and detailed user permission settings. This results in reduced overstock, increased inventory turnover, and complete visibility into stock movements.

Significant Labor Reduction

Labor costs are significantly reduced—by up to 75 percent—thanks to full automation from the inbound point to outbound flow. Processes such as sorting, storing, and transferring goods are performed without human intervention, helping businesses operate more efficiently while cutting down on operational costs.

Flexible Design and Configuration Options

In addition, the Eurorack ASRS offers flexible configuration options to fit different warehouse needs. From varying structural dimensions to integrated conveyor belt systems, every component is engineered for compatibility and seamless material flow across distinct operational zones.

Fast and Accurate Item Retrieval

The system ensures high selectivity, enabling quick, timely, and accurate product retrieval. Operators can access required items without delay, which improves response time and service reliability.

Forklift-Free Operation and Workflow Integration

Another advantage lies in its adaptability. ASRS cranes can retrieve goods directly from racks without the need for forklifts and deliver them to designated packaging or dispatch areas. This smooth transition between storage and handling stages enhances workflow and safety.

Large-Scale Storage with Full Accessibility

With large-scale storage capability and one hundred percent access to all stored items, the Eurorack ASRS Racking System is a robust, intelligent solution for modern warehouses aiming to scale operations, reduce costs, and maintain complete control over inventory.

What Industries Can Benefit Most from Eurorack’s ASRS System?

The Eurorack ASRS racking system is designed to meet the high-performance demands of modern supply chains across a wide range of industries. With its precision, speed, and storage efficiency, ASRS is particularly well-suited to sectors that require strict inventory control, high throughput, and space optimization. Key industries that benefit most from Eurorack’s ASRS solutions include:

Cold Storage and Food & Beverage

ASRS systems thrive in temperature-controlled environments where minimizing human exposure is critical. Eurorack ASRS ensures efficient pallet handling in freezing conditions, while preserving product integrity, meeting food safety regulations, and maximizing the use of expensive refrigerated space.

Pharmaceuticals and Medical Supplies

In industries where traceability and accuracy are non-negotiable, ASRS offers real-time inventory tracking, batch control, and secure access. Eurorack's high-density, sterile-compatible systems help ensure compliance with strict industry regulations.

E-Commerce and Retail Distribution

The fast-paced nature of online and retail fulfillment demands speed, selectivity, and inventory visibility. Eurorack ASRS enables fast picking, handles a wide range of SKUs, and scales effortlessly to accommodate seasonal demand spikes without adding warehouse labor.

Manufacturing and Industrial Production

Manufacturers rely on just-in-time delivery of raw materials and components. ASRS helps ensure continuous material flow to the production line, reduces downtime, and provides efficient storage of parts, tools, and finished goods—all while maximizing space in production-adjacent areas.

Automotive and Heavy Equipment

Eurorack ASRS handles bulky, high-value components with ease, enabling precise placement, secure storage, and damage-free retrieval. Ideal for managing large SKUs and keeping critical parts readily available in service or assembly operations.

Logistics and 3PL Providers

Third-party logistics companies must balance speed, accuracy, and adaptability. Eurorack’s scalable ASRS systems offer high throughput, multi-client inventory handling, and seamless WMS integration, making them a smart choice for logistics hubs and shared distribution centers.

ASRS is an automated storage solution that helps enterprises optimize warehouse space, increase inbound and outbound speed, improve inventory accuracy, and significantly reduce labor costs. With a flexible design, stable operation, and long term scalability, ASRS is well suited for manufacturing warehouses, logistics centers, e commerce fulfillment, and cold storage facilities. Contact Eurorack today to receive on site assessment and practical consultation tailored to your warehouse operations.

.jpg)

.jpg)

.jpg)