- Hotline: (+84) 938 520 379

- Email: info@eurorack.com

EURORACK MECHANICAL JSC

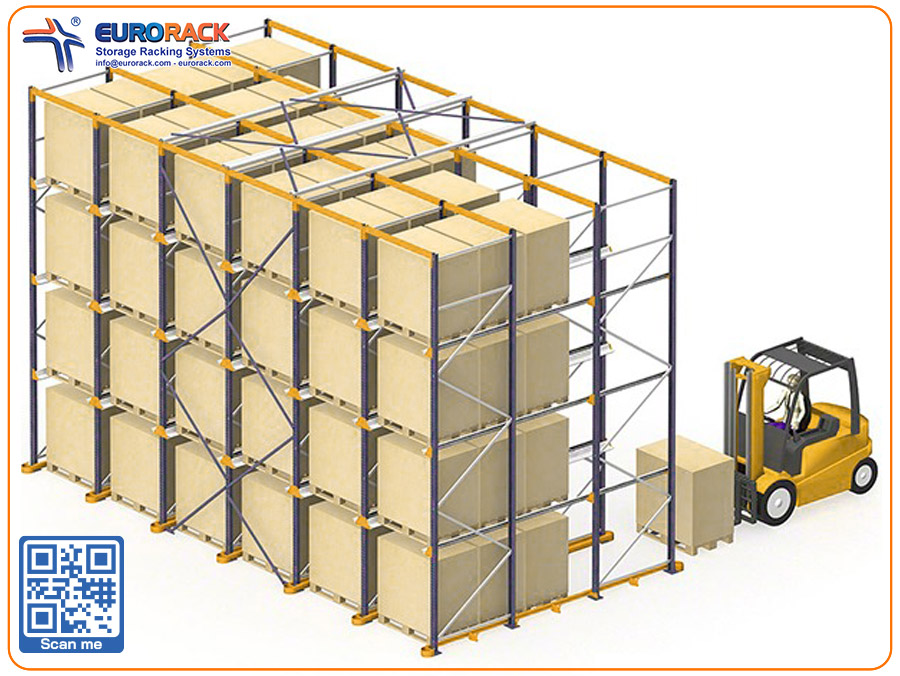

Drive In racking is a high density storage solution, suitable for warehouses that need to maximize space utilization while handling a limited number of SKUs. The system allows forklifts to drive directly into the racking structure to load and retrieve pallets, enabling businesses to significantly increase warehouse capacity without expanding floor space. With its focus on batch storage, Drive In racking is commonly applied in cold storage, raw material warehouses, and facilities where products have stable life cycles.

In real world operations, the effectiveness of Drive In racking depends not only on its ability to increase storage capacity, but also on how well the system is designed to match the type of goods, forklift specifications, and the inbound and outbound handling processes of each warehouse. Selecting the right configuration from the outset helps businesses fully utilize available space while minimizing collision risks and long term operational costs.

Drive In racking operates based on the LIFO principle, where the last pallet loaded is the first to be retrieved. Instead of using beams like Selective racking, pallets are placed directly on guide rails mounted on both sides of the racking frame, allowing forklifts to drive deep into each lane for handling operations. Thanks to this operating principle, the system minimizes forklift aisles and maximizes storage density. However, Drive In racking is truly effective only when used for uniform goods, batch storage, and applications that do not require flexible access to individual pallets

Explore Drive In pallet racking systems together with Eurorack

Drive In racking systems offer several outstanding advantages as follows:

Each design solution delivers optimal application advantages within industrial storage environments. If you are considering installing this racking system, please contact Eurorack directly via hotline 0938 520 379 for detailed consultation and technical support.

Eurorack Drive In racking features high load capacity and durability, ideal for production material warehouses

Drive In pallet racking is widely used across various warehouse models characterized by batch storage:

In addition to its storage density advantages, Drive In racking is not suitable for warehouses with a wide variety of SKUs or those requiring fast and flexible pallet access. Forklifts operating deep inside the racking lanes require precise design, consistent guide rail alignment, and well defined operating procedures to ensure safety and long term system durability. Therefore, Drive In racking must be carefully engineered from the design stage rather than installed using generic standard dimensions.

The Drive In pallet racking system consists of 8 basic components:

Eurorack is a direct designer and manufacturer of Drive In racking systems in accordance with European technical standards, meeting high load requirements and long term structural stability. Each system is flexibly engineered based on actual warehouse conditions, pallet types, and individual operating methods, rather than applying a fixed standard configuration. Eurorack’s engineering team provides site surveys, layout consultation, and tailored solution proposals to help businesses optimize investment costs while ensuring operational safety and long term efficiency.

With more than 10 years of continuous effort, ongoing research, and the application of advanced engineering technologies in manufacturing, Eurorack is proud to be a trusted partner for many leading brands such as Nestlé, Ajinomoto, CJ Food, and FPT.

Drive In racking and Shuttle racking are both high density storage solutions designed to optimize warehouse space by reducing forklift aisles. However, these two systems serve different stages of warehouse development and adopt completely different operational approaches. The key differences are outlined below:

Drive In racking requires forklifts to drive directly into the racking lanes to place and retrieve pallets. This approach maximizes space utilization but relies heavily on operator skill and inevitably involves a higher risk of collision during long term operation. In contrast, with Shuttle racking, forklifts do not enter the racking lanes. Pallets are placed at the front of each lane, after which the Eurorack WiFi Shuttle robot automatically transports the pallet to its storage position. This difference significantly reduces collision risks while enhancing overall system stability and extending racking service life.

Drive In racking increases storage density compared to Selective racking and is particularly suitable for warehouses with deep storage lanes and a limited number of SKUs. However, the usable depth of Drive In systems is still constrained by safe forklift access. Shuttle racking allows full utilization of both warehouse depth and height, even with very deep lanes, as it is not limited by forklift reach. This is why Shuttle systems are often selected for warehouses with high pallet volumes and where maximum space optimization is required.

With Drive In racking, forklifts frequently operate inside the racking structure, making collisions with uprights and guide rails difficult to avoid, especially in cold storage environments or high throughput warehouses. In comparison, Shuttle racking virtually eliminates direct contact between forklifts and the racking structure. This not only improves workplace safety but also helps maintain structural accuracy and stable load bearing performance over extended periods.

Drive In racking is suitable for warehouses with moderate throughput, batch storage, and no requirement for rapid pallet retrieval. Shuttle racking offers significantly higher handling speed. Automating the pallet movement into and out of storage lanes increases inbound and outbound productivity, reduces forklift waiting time, and optimizes workforce efficiency.

Drive In racking is cost effective in terms of initial investment, but its upgrade potential is relatively limited. When higher throughput or increased safety requirements arise, the system often requires major modification or replacement. Shuttle racking is designed as a semi automated solution, allowing easy expansion through additional Shuttle units, extended racking lanes, or integration with warehouse management solutions as business needs grow. This makes it a suitable choice for warehouses with long term expansion plans.

When should Drive-In racking be used?

Drive-In racking is an ideal choice for warehouses that need to store large quantities of uniform goods under the LIFO method, such as construction materials, chemicals, or industrial components. This system is suitable when businesses aim to optimize space by minimizing aisle areas, especially in warehouses with limited floor space. With a storage depth of up to 8 pallets, Drive-In racking helps improve warehouse organization and supports long-term inventory management.

Is Drive-In racking suitable for cold storage warehouses?

Absolutely. Drive-In racking is highly suitable for cold storage environments thanks to its anti-corrosion powder coating and stable operation at temperatures as low as -30°C. The system meets GMP requirements by ensuring safe storage for frozen food products such as meat or ice cream. Its high-density design helps reduce refrigeration costs and is ideal for export-oriented cold storage facilities that require long-term LIFO storage.

How can safety be ensured when forklifts operate within Drive-In racking lanes?

Drive-In racking is equipped with pallet guide rails and safety barriers to support precise forklift movement and reduce the risk of collisions. Before each working shift, warehouse staff should inspect the pallet rails, upright frames, and safety barriers to ensure there is no damage. In addition, forklift operators must receive thorough training to operate safely in narrow aisles, particularly in industrial or chemical warehouses with high traffic volumes.

Can Drive-In racking be customized to store non-palletized goods?

Yes. Drive-In racking can be customized with steel decking or wire mesh shelves to store non-palletized goods such as cartons or loose items. This is especially useful for logistics warehouses handling small products like electronic accessories, helping maintain an organized layout and easy access under the LIFO principle.

How should Drive-In racking be inspected before operation?

Before operation, businesses should inspect the upright frames, pallet rails, safety barriers, and powder-coated surfaces to ensure there is no damage or misalignment. Bolts should also be tightened if necessary to maintain system stability. This inspection process is particularly important for cold storage facilities, where ensuring product safety and minimizing risks in low-temperature environments are critical.

Can Drive-In racking be integrated with automated warehouse management systems?

Yes, Drive-In racking is fully compatible with AGVs (automated guided vehicles) and WMS, helping reduce picking errors and improve operational efficiency. In logistics warehouses, integrating AGVs with Drive-In racking supports faster material handling under the LIFO principle, saving time and labor, especially in environments storing uniform goods.