- Hotline: (+84) 938 520 379

- Email: info@eurorack.com

EURORACK MECHANICAL JSC

| Specification | Detail |

| Rated Load | 1600 ~ 2000 kg |

| Operating Speed | 1.5 – 2.0 m/s |

|

Loading Speed

|

45 ~ 50 m/min

|

|

Unloaded Speed

|

70 ~ 75 m/min

|

| Reversal Time | 2.5 s |

| Accuracy of Positioning | ±2 mm |

| Battery Capacity | 40 AH |

| Charge Time | 1 .5 –3 h |

| Battery Type | Lithium Iron Phosphate |

| Battery Life | 8 - 10h |

| Applicable Temperature | -30°C ~ 50°C |

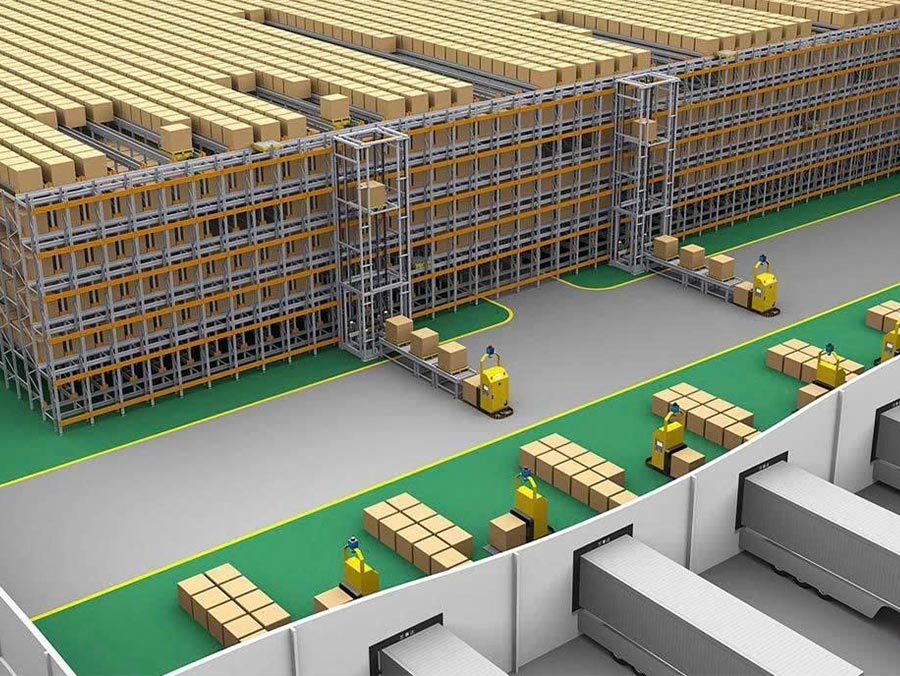

Eurorack Four-Way Shuttle: An intelligent shuttle robot capable of handling pallets weighing from 1,500 to 2,000 kg, operating at speeds of up to 72 meters per minute. It ensures fast and safe pallet transport.

Lift Platform: An automatic lifting device that transfers the shuttle and pallets between racking levels with high precision, supporting fast and stable goods circulation.

Smart Charging Station: Powered by lithium batteries, it enables fast charging within 90 minutes and supports continuous operation for up to 8 hours in cold storage and 10 hours in standard warehouse environments.

Warehouse Management Software (WMS/WCS): Integrates a smart Warehouse Management System (WMS) and Warehouse Control System (WCS), enabling precise pallet tracking, efficient shuttle navigation, and seamless connectivity with enterprise systems such as ERP or SAP.

Safety Sensors: Automatically detect humans and obstacles, ensuring maximum safety during operation.

Integrated System: Eurorack’s shuttle system can be flexibly integrated with other automation solutions such as conveyors, Automated Guided Vehicles (AGVs), and industrial robots, creating a fully automated logistics chain.

|

|

|

|

|

|

|

|

In a context where warehouses need to store more goods without expanding floor space, while still ensuring safety and optimized operations, the Four Way Shuttle racking system is a suitable solution for Enterprises moving toward full automation. Eurorack is ready to conduct on site surveys, provide optimal solutions, and support long term operations. Contact us now for assistance.

1. Task Initialization by WMS: The Warehouse Management System (WMS) initiates a storage task by identifying an available location based on real-time inventory data, product type, and warehouse optimization logic. This task is then assigned to the Eurorack Four-Way Shuttle System for execution.

2. Pallet Arrival at Inbound Station: The pallet is physically transported to the inbound station using a forklift, conveyor system, or automated guided vehicle (AGV). Sensors at the inbound area detect the pallet's arrival and confirm it is ready for processing.

3. Instruction Transfer to Eurorack Shuttle via WCS: The Warehouse Control System (WCS) communicates directly with the Eurorack Four-Way Shuttle, transmitting precise instructions that include the pallet’s dimensions, weight, and the exact destination within the storage grid.

4. Pallet Pickup and Horizontal Navigation: The Eurorack shuttle autonomously moves to the inbound station. Using its telescopic forks or lifting platform, it lifts the pallet securely and begins traveling horizontally through the racking system. Thanks to its ability to move forward, backward, left, and right, the shuttle navigates both storage lanes and main aisles efficiently without the need for forklifts or track switching.

5. Pallet Placement and Confirmation: Upon reaching the assigned storage location, the Eurorack Four-Way Shuttle carefully places the pallet into the racking structure. Its onboard sensors ensure accurate positioning with millimeter-level precision. Once the task is complete, the shuttle sends a confirmation to the WCS, which updates the WMS to reflect that the pallet has been successfully stored.

1. Outbound Task Triggered by WMS: When a pallet is needed for shipping or order fulfillment, the WMS creates an outbound task and sends the retrieval instruction to the WCS. The system then dispatches the Eurorack Four-Way Shuttle to handle the request.

2. Shuttle Navigation to Storage Location: The shuttle autonomously travels through the racking system to the precise location of the required pallet. Its navigation relies on a combination of QR codes, RFID tags, and advanced laser alignment technology, ensuring smooth and accurate positioning.

3. Pallet Extraction from Rack: Once positioned, the Eurorack shuttle lifts the pallet from the storage bay using its integrated handling mechanism. Safety sensors and load detection features ensure secure and stable movement throughout the process.

4. Delivery to Outbound Station: The shuttle then navigates through the warehouse toward the outbound station. Upon arrival, it places the pallet onto a designated conveyor, AGV platform, or handoff point, ready for pickup by forklift or automated transfer system.

5. System Update and Task Completion: After successful pallet delivery, the Eurorack Four-Way Shuttle System notifies the WCS, which in turn updates the WMS to reflect the inventory change and task completion. This ensures real-time visibility and full synchronization across all warehouse operations.

With over fifteen years of experience in manufacturing and implementing automated warehouse systems, Eurorack has built a solid reputation for delivering reliable and high performing solutions that comply with international standards. From the initial concept through to final commissioning, every phase is managed internally, including system design, precision manufacturing, on site installation, and technical maintenance. This approach ensures smooth coordination, cost effectiveness, and consistent quality throughout the entire project.

Recognizing that every warehouse has its own set of challenges, Eurorack provides flexible and fully customized systems tailored to specific industries, facility layouts, environmental conditions, and operational requirements. Whether the application is in a smart manufacturing plant, a cold storage warehouse, or a dense distribution center, each solution is engineered to deliver long lasting performance and scalability.

Even after installation, Eurorack continues to be a dependable partner by offering round the clock technical support, fast service response, and a steady supply of certified replacement parts. Our long term service commitment helps maintain system availability, operational safety, and efficiency at all times.

Respected by global businesses across a wide range of industries, Eurorack is more than just a provider of automation technology. We are a strategic partner focused on improving your warehouse operations today while preparing you for the challenges and opportunities of the future.