- Hotline: (+84) 938 520 379

- Email: info@eurorack.com

EURORACK MECHANICAL JSC

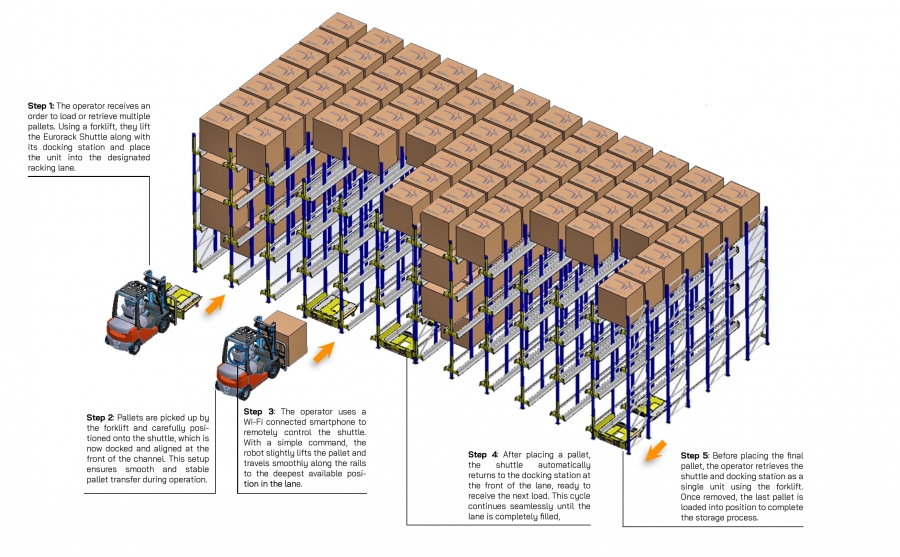

The Eurorack Wifi Shuttle is a high-density pallet storage system engineered to maximize warehouse performance through intelligent automation and precision engineering. Controlled via a WiFi-connected tablet, the shuttle receives operator commands to load or retrieve pallets automatically. Built with German technology and equipped with high-precision SICK sensors, the Eurorack Wifi Shuttle offers reliable detection, accurate positioning, and consistent performance even under demanding conditions such as dusty warehouses or cold storage (operating temperature range: -30°C to +50°C).

Supporting both FIFO (First In, First Out) and LIFO (Last In, First Out) inventory strategies, this shuttle provides exceptional flexibility for a wide range of industries, including cold storage, food and beverage, pharmaceuticals, and any operation where space optimization and inventory control are critical.

1. Beam: Supports guide rails and connects upright frames.

2. Upright frames: Main vertical structure supporting the rack.

3. Guide rail: Guides shuttle movement within the rack.

4. Eurorack Wifi Shuttle: WiFi-controlled pallet shuttle robot.

5. Smart Control: Operates shuttle via smartphone or tablet.

6. Charging Station: Automatic battery charging area for the shuttle robot, ensuring it is always ready for operation and minimizing downtime from manual battery replacement.

7. Safety Sensors: German-made sensors detect obstacles to protect operators and goods during movement.

8. Front/End Stopper: Secures pallets in position and prevents sliding or falling from the rack during high-speed operations.

The Eurorack Wi-Fi Shuttle is equipped with a high-performance motor that delivers stable power output and smooth motion control. Its energy-efficient design reduces vibration and noise while maintaining precise pallet movement under continuous operation. This ensures reliable performance even in intensive warehouse environments, extending equipment lifespan and minimizing maintenance costs.

Built for industrial-grade performance, the motor features intelligent torque control and thermal protection for extended durability. It operates consistently across varying load conditions, providing strong acceleration and steady braking. These features collectively enhance energy efficiency and ensure stable handling during high-frequency operations.

Equipped with high-precision sensors imported from Germany, the Eurorack Wi-Fi Shuttle ensures accurate obstacle detection, precise positioning, and consistent operation in all warehouse environments. These industrial-grade sensors maintain stability even in dusty or low-temperature conditions, guaranteeing safety and optimal performance for every shuttle movement.

The sensors continuously monitor movement and surroundings to prevent collision and misalignment. Their fast response time enhances automation accuracy and reduces error margins during pallet transfers. This advanced sensing system improves both safety and operational reliability throughout the warehouse.

Wirelessly controlled via an industrial tablet or smartphone, the system offers intuitive operation and enables remote control with ease — enhancing efficiency and user accessibility in warehouse environments.

A tablet or smartphone can control multiple Eurorack Shuttles at once. It supports remote activation, shows the battery status of both the device and the shuttles, and sends automatic notifications about maintenance schedules to keep operations running smoothly.

This digital interface allows seamless integration with warehouse management systems (WMS) for real-time monitoring. Operators can set routes, manage storage tasks, and receive system alerts instantly. The wireless control reduces manual input, improving accuracy and workflow automation.

ST Model: Designed for standard warehouse environments, this model ensures stable performance at temperatures up to +50°C, making it ideal for ambient storage operations.

BZ Model: Specially engineered for cold and freezer storage, this version operates reliably in extreme conditions down to -30°C. Its reinforced components and low-temperature resistant electronics ensure continuous, safe performance in chilled or frozen environments.

Both versions are built to maintain consistent power delivery, regardless of temperature variations. This adaptability helps businesses streamline operations across different warehouse types, from dry goods to frozen food storage, without needing separate equipment sets.

When the battery level reaches a preset threshold, the Eurorack Wi-Fi Shuttle automatically returns to its designated charging or pick-up point after completing its current task. This smart feature prevents unexpected downtime, allowing for timely battery replacement or recharging without interrupting warehouse operations. It ensures continuous workflow, higher equipment availability, and overall operational efficiency.

The return function is supported by intelligent navigation and real-time communication with the control system. This ensures smooth coordination between multiple shuttles during operation. As a result, the system maintains productivity while optimizing energy usage and minimizing manual intervention.

The Eurorack Wi-Fi Shuttle Advanced is designed for warehouses that require maximum storage capacity in limited space. By eliminating the need for forklift aisles and enabling rack depths of up to 80 meters, the system maximizes both horizontal and vertical storage space. Its reinforced structure and optimized height-to-depth ratio allow more pallets to be stored within the same footprint.

For operations that involve high volumes of identical palletized goods, the Eurorack Shuttle enables an entire rack row to be allocated to a single SKU or product batch. This simplifies warehouse organization and significantly reduces pallet handling time, without the need for complex sorting or unit-level processing.

The Eurorack Shuttle significantly accelerates inbound and outbound operations, making it an ideal solution for fast-moving goods or high-frequency shipping warehouses. The system ensures continuous pallet flow, minimizing bottlenecks at entry and exit points. With a speed of 50 m/min (loaded) and 75 m/min (unloaded), the shuttle supports high-intensity operations in modern logistics centers.

By eliminating the need for forklifts to enter the racking system and reducing repetitive manual handling, the Eurorack Shuttle helps cut down on operating and maintenance costs. Warehouses benefit from lower fuel consumption, reduced equipment wear, and improved safety. With less manual intervention required, staff can be reassigned to higher-value tasks such as system supervision, process optimization, and strategic planning—ultimately increasing overall productivity.

Equipped with sensors and remote control functions, the shuttle system enables precise real-time inventory tracking. Pallets are automatically counted, and integration with Warehouse Management Systems (WMS) provides accurate, up-to-date stock data, minimizing discrepancies and enhancing transparency in warehouse operations.

The Eurorack Shuttle operates reliably in temperatures as low as -30ºC, making it ideal for cold and freezer storage environments. Its compact design reduces the volume of air that needs to be cooled, saving energy and improving cold space utilization—key factors in industries like food, seafood, pharmaceuticals, and frozen goods.

The Eurorack Shuttle improves warehouse safety by minimizing forklift activity and manual labor within the racking area. This significantly reduces the risk of operator injuries, pallet damage, and structural collisions. The system is particularly beneficial in high-traffic, narrow-aisle environments where worker protection and product integrity are critical.

To support a wide range of warehouse needs, the Eurorack Shuttle System offers two distinct operating modes, each optimized for different storage and inventory turnover requirements:

FIFO mode (First In, First Out): This mode is ideal for perishable goods or products with limited shelf life. It requires access from both ends of the racking lane.

LIFO mode (Last In, First Out): This mode allows pallet input and output from the same side, making it well-suited for high-density storage applications.

The Eurorack Wifi Shuttle is compatible with multiple rail system configurations

Over the years, Eurorack has modernized its production of warehouse racking systems by importing top-tier mechanical production lines from Europe and Japan. Supported by a team of highly skilled engineers, Eurorack has automated many production stages to minimize costs. The result is competitively priced, high-quality products that meet ISO 9001:2015 standards for safety and reliability.

Reasons to Choose Eurorack Pallet Shuttle Racking

These insights into the Pallet Shuttle Racking System highlight the benefits of using Shuttle Robots in warehouse storage. The Eurorack Wi-Fi Shuttle Robot, with its advanced features and user-friendly design, provides a smart and efficient solution for modern warehouses.

Contact Eurorack today for intelligent storage solutions and warehouse automation that is both effective and optimized.

Radio Shuttle and Eurorack Wifi Shuttle are two popular robot models designed to optimize storage in Pallet Shuttle Racking Systems. However, they differ significantly in design and operation, offering varying levels of flexibility and control.

This is the first-generation Shuttle Robot, controlled via radio frequency signals. Operators use a remote control within a limited range to position pallets accurately based on manual commands. This type of robot has relatively limited automation capabilities, performing only basic tasks.

This is an upgraded Shuttle Robot featuring a modern design and more advanced technologies compared to the Radio Shuttle. It is controlled through industrial tablets or smartphones connected via Wi-Fi, allowing operators to manage the robot from anywhere without spatial limitations.

Notably, the Eurorack Wifi Shuttle can perform advanced functions such as continuous pallet loading and unloading, pallet sorting, pallet counting, and obstacle detection to ensure workplace safety. Additionally, it tracks the number of pallets processed daily, enabling efficient warehouse workflow management.

The Eurorack Wifi Shuttle Robot represents a significant technological improvement over the traditional Radio Shuttle, with a focus on increased automation, efficiency, and user convenience. Its ability to perform complex tasks with precision and safety makes it an indispensable tool in modern warehousing.

Video introducing Eurorack Wifi Shuttle Automatic Racking at the exibition

|

|

| Eurorack at Exhibition 1 - 2025 | Eurorack at Exhibition 2 - 2025 |

|

|

| Eurorack at Exhibition 3 - 2025 | Eurorack at Exhibition 4 - 2025 |